Nitrogen Generators

Nitrogen is used as a clean, dry, inert gas primarily for removing oxygen from products and/or processes, in a wide range of industries such as food, beverage, pharmaceutical, chemical, heat treatment, electronics, transportation, oil and gas, and laser cutting.

N2 Generators from Parker

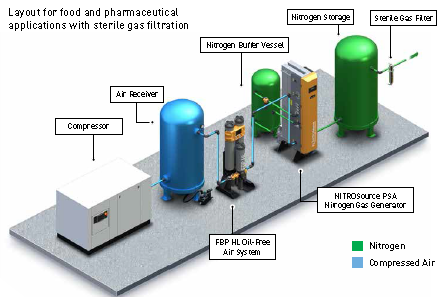

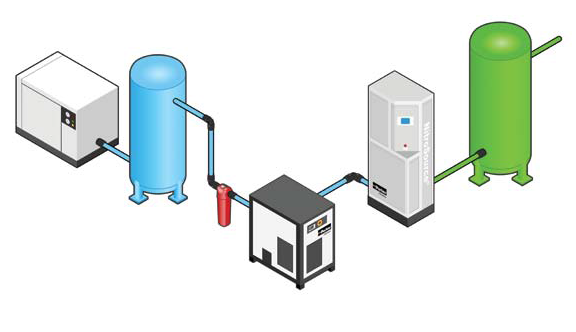

Provide an on-demand continuous source of nitrogen gas from compressed air in accordance with European standards, and offer a cost-effective, reliable and safe alternative to traditional nitrogen gas supply such as cylinders or liquid.

Technologies

PSA technology consists of two parallel vessels filled with Carbon Molecular Sieve (CMS), a material which adsorbs oxygen under pressure, allowing nitrogen to pass through the sieve material into an oxygen-free receiver vessel. The oxygen is then discharged as exhaust. Clean, dry compressed air is introduced and fed into the CMS towers during alternating cycles: one generates nitrogen while the other regenerates under low pressure. High-purity nitrogen is consistently released to the application point, while oxygen is removed from the CMS and vented safely.

These consist of hollow fibers. The walls of these fibers are selective membranes composed of polymer material which allow gases to be separated by their differing speeds. Oxygen and water vapor pass quickly through the membrane, while nitrogen takes longer, remaining in the core of the fibers to the application point.

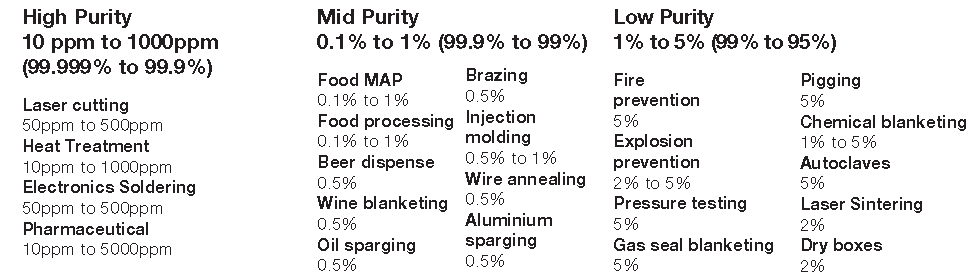

Applications

PSA N2 generators: Best suited for industries requiring medium to high (99–99.999%) nitrogen purity, such as pharmaceuticals, chemical processing, metal fabrication & laser cutting, electronics manufacturing, stone food and beverage production.

Membrane N2 generators: Suitable for applications that require low to medium (95–99.5%) nitrogen purity, such as tire inflation, fire prevention, MAP packaging & some food and beverage processes.

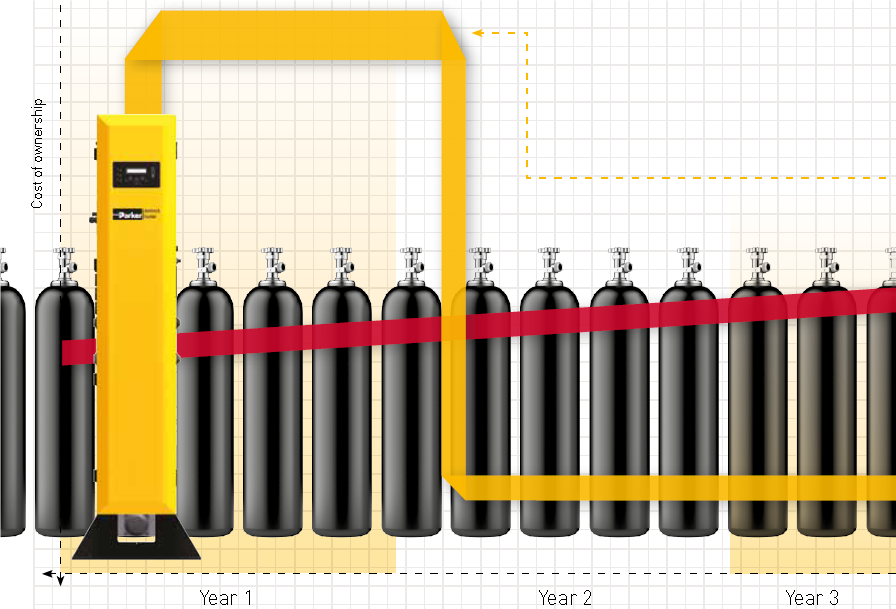

The most economical source of nitrogen

When traditional nitrogen sources such as cylinder gas or liquid N₂ are used, on-site gas generation offers a reliable, cost-effective, and sustainable solution for most industries.

Benefits:

- Up to 90% cost savings – Typical capital payback is achievable within 12–24 months.

- Convenient and safe – This gas system is simple to install, requires minimal maintenance and eliminates delivery costs and risks associated with gas storage.

- Space-efficient and expandable – The system demands less floor space.

- Flexible multi-bank option – The modular concept means the generator can be multi-banked if required.